Logistics Automation Service

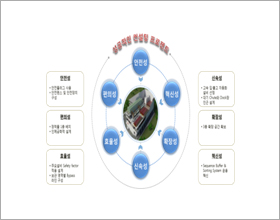

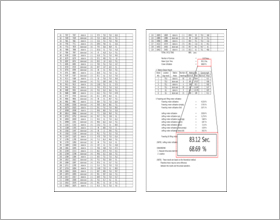

Simulated Performance Prediction

Minimization of Energy Consumption by Optimizing Logistical Flow

Optimization of Logistical Process (Reduction of Standby Time, Simplification of Picking and Sorting, and Removal of Disuse Time)

HYUNDAI’s Logistics Automation Service finds the logistical value pursued by the customer based on deep consideration of diverse automation technologies and logistical process and realizes it as a system.

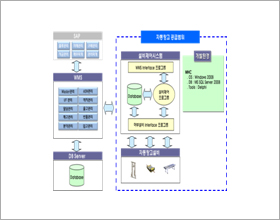

System characteristics

Data Analysis

(IQ, EIQ, ABC Analysis)

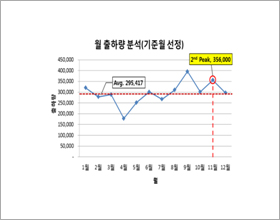

Time Series Analysis

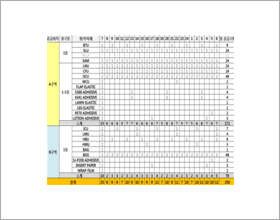

Material Flow Analysis

Design Key Point Analysis

Logistics Information Analysis

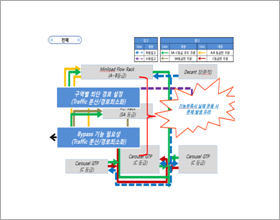

Cycle Time Tool

Facility Selection Methods

System Simulation

We use the following optimization solutions to realize the value system that our customers pursue.